Preventive Maintenance Manufacturing

Manufacturing equipment is a huge investment. The longer it stays running, the more you get out of it. You can keep your equipment running longer with preventive maintenance, sometimes abbreviated as PM.

Preventive maintenance reduces the chances of equipment failure and unplanned downtimes. With unplanned downtime costing industrial manufacturers an estimated $50 billion each year (Forbes), and 42% of unplanned downtime being because of equipment failure (WSJ), preventive maintenance seems almost obligatory.

What is preventive maintenance in manufacturing?

Preventive maintenance in manufacturing is the process in which companies can extend the operational lifespan of equipment by establishing proactive preventive maintenance schedules. The goal of PM is to plan and schedule maintenance before a problem occurs.

Scheduled preventive maintenance helps companies avoid equipment breakdowns through regular, routine maintenance, including cleaning, adjustments, repairs, lubrication, and replacements. It is like the weekly chore list you may have had growing up… except returns could be in the thousands instead of just a measly allowance. PM can even play into a lean manufacturing strategy, as it lowers waiting and defect waste.

To simplify, the five goals of preventive maintenance are to:

- Replace parts before they fail

- Clean parts before performance degrades

- Avoid equipment and part failure

- Improve reliability and predictability

- Train others on proper maintenance

These are done through the use of systematic, routine checks. In this guide, we will explain why and how to implement preventive maintenance in your business.

The benefits of preventive maintenance

Most people bring their car in for regular check-ups when it reaches a certain mileage. They want to get ahead of any potential vehicle maintenance issues. The same should apply to your production equipment.

The benefits of preventive maintenance include:

- Longer lasting equipment

- Better equipment performance

- Fewer defects

- Less downtime / more production time

- Increased safety

- Reduced costs

Equipment that is not running at an optimal pace will slow down output. If equipment is making 80 pieces an hour instead of the optimal 100, that translates into 160 fewer pieces a day or 800 fewer a week. Facility managers can prevent inefficient performance and failure with PM.

The different types of maintenance strategies

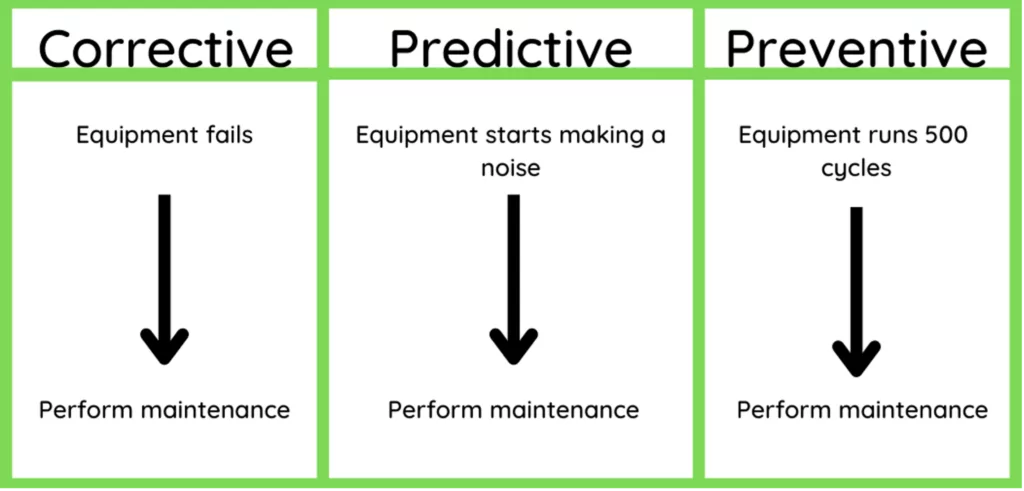

There are mainly three types of maintenance strategies:

Or reactive maintenance, means performing maintenance after equipment failure.

Means monitoring equipment conditions and predicting when maintenance is necessary based on the equipment conditions, real-time data, and knowledge about the equipment.

Means planning maintenance based on real-time data and equipment knowledge. Businesses can save 12-18 percent by switching from corrective maintenance to preventive maintenance (EERE).

Examples of each are below:

The difference between preventive and predictive maintenance strategies is that predictive maintenance only occurs when it is necessary. As a result, predictive maintenance does lower maintenance frequency, but there are two drawbacks.

- Equipment checks are often more frequent with preventive maintenance, so preventive maintenance is more effective at preventing unexpected breakdowns and lessening the consequences.

- You can also plan maintenance during production downtimes with preventive maintenance, instead of requiring maintenance based on conditions.

The different types of preventive maintenance

There are two different types of preventive maintenance:

- Time-based preventive maintenance occurs at specific intervals of time, like every Monday.

- Usage-based preventive maintenance occurs when usage hits a benchmark, like every 200 production cycles.

Nowadays, most equipment can track usage time or number of cycles for employees.

Facility managers have long argued which method of preventive maintenance is best. The thing is both have benefits. The Next Step learned from years of experience that preventive maintenance should be chosen based on the equipment and its usage. Each equipment should get its own preventive maintenance schedule to prevent unplanned failures. If a piece of equipment is operational 24 hours a day, a usage-based preventive maintenance schedule is more effective. If it is used only once or twice a day, time-based is better.

How do you determine which type to use for each equipment?

The original equipment manufacturer (OEM) often provides recommendations on how best to maintain equipment. Equipment data can also be collected over time and analyzed using software like a CMMS, or computerized maintenance management system. Effective preventive maintenance schedules consider OEM-recommended maintenance frequency, real-time data insights, and equipment usage.

How to make a preventive maintenance schedule

Preventive maintenance schedules take fine-tuning to ensure preventive maintenance tasks are scheduled only when necessary. The goal is to not do maintenance too often (which costs time and money) or too seldom (which increases the likelihood of failures).

The best way to create and improve a preventive maintenance plan is with a revised PDCA plan (Plan, Do, Check, Act):

- Plan your preventive maintenance schedules for each equipment based on OEM maintenance schedules, usage patterns, and repair histories.

- Incorporate the preventive maintenance schedules in your production schedule to avoid downtime.

- Do the preventive maintenance schedule consistently.

- Document in a maintenance log when you do maintenance.

- Check that your plan is working and followed through on.

- Look at the failure metrics for equipment and the maintenance log.

- Act on the results.

- If equipment is failing between scheduled maintenance, increase the frequency of preventive maintenance and vice versa.

The preventive maintenance workflow is illustrated below:

Of course, every business has unique processes. Steps may need to be added, removed, or adjusted. Businesses also make preventive maintenance checklists/schedules at different levels of detail. Some large businesses use preventive maintenance software that interacts with the equipment to schedule maintenance automatically.

Preventive maintenance software is extremely helpful. Tracking data manually is logistically difficult, so the software simplifies the process and alerts managers when PM is needed. You can also analyze data about preventive maintenance tasks to easily set maintenance KPIs, discover frequently occurring problems, and improve your scheduling.

Learn more about preventive maintenance software and manufacturing automation.

Five tips for making a preventative maintenance schedule

Our operations experts at The Next Step have spent decades implementing and running preventive maintenance programs. They have assembled five essential PM tips:

Before purchasing equipment, thoroughly understand the maintenance needs and associated costs.

Decide which equipment to purchase based on your needs and the equipment’s upkeep.

Stay consistent with your preventive maintenance.

If you skip PM because you can’t have equipment down, it will eventually crash and cause bottlenecks.

Schedule maintenance during off-shifts to prevent production downtime.

Good scheduling will identify time for output/production and time for preventative maintenance.

Duplicate equipment allows you to maneuver around the failures.

You can skip maintenance at the risk of your equipment going down if you have duplicate equipment.

Maintain a stock of backup pieces that are critical to your equipment.

Repairs will be quicker.

How we can help

Preventative maintenance is necessary for the ownership of equipment. If you don’t maintain your equipment properly, expect short-term productivity issues and long-term equipment lifespan issues.

The Next Step offers preventive maintenance services based on decades of manufacturing experience. We can help identify equipment purchases, set up schedules, lay out preventive maintenance expectations, and more.

Save time and find clarity.

Contact us today to discuss your business’ maintenance needs.